Say Hello To: Iris Inez

1973 Samson Marine Port McNeill 55' Trawler

Listing Price:

50000

LOA: 58 ft

Beam: 15.5 ft

Max Draft: 6.5 ft

Engine GPH: 1.6

Engine Hours: ~2600

DESCRIPTION

Iris Inez is a Samson Marine built ferro-cement long range, Vospar stabilized trawler. She was originally built for the California inventor and engineer, Vard Wallace, with each and every fitting being cast in bronze at his foundry.

She has a 4,000-4,500nm range on 850 gallons of diesel with newer stainless steel tanks that replaced the original fiberglass tanks. She also has ~1,000 gallons of water that can be held onboard in three tanks.

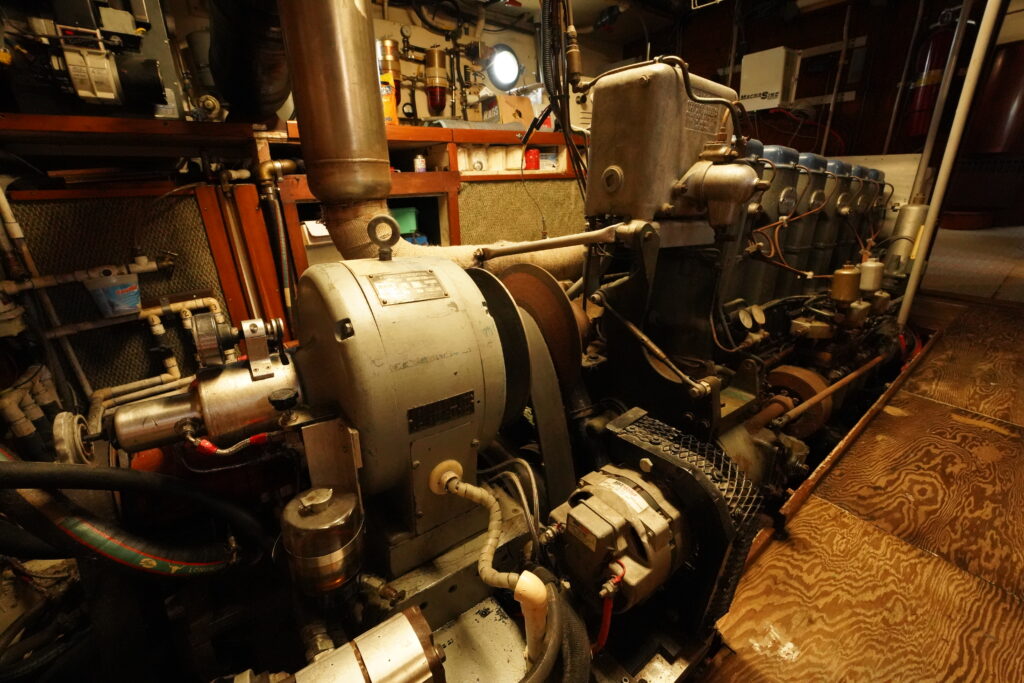

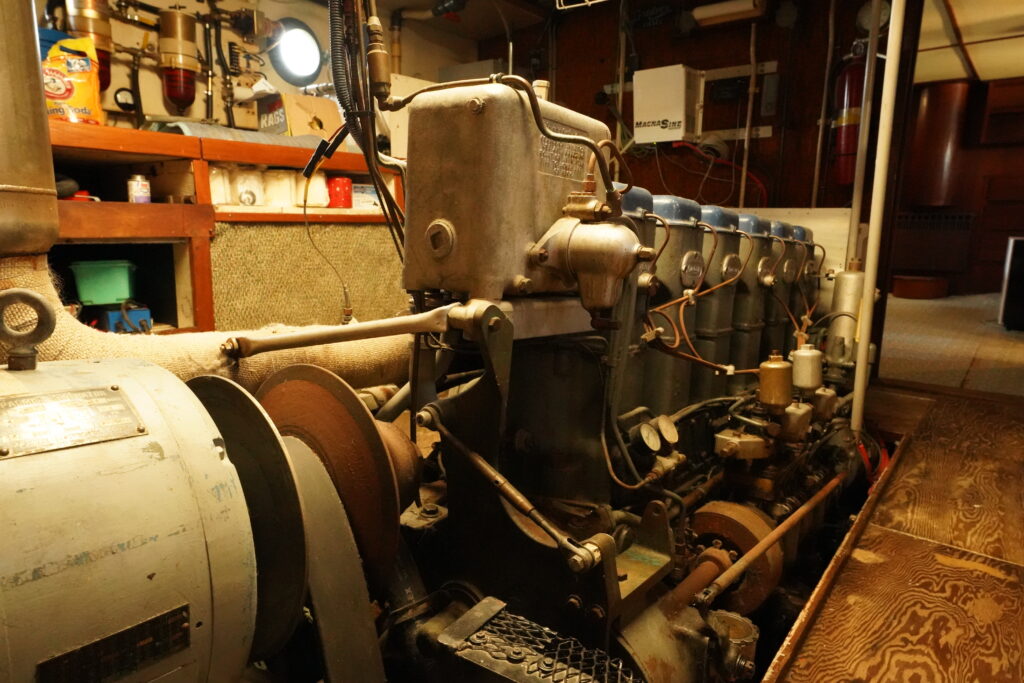

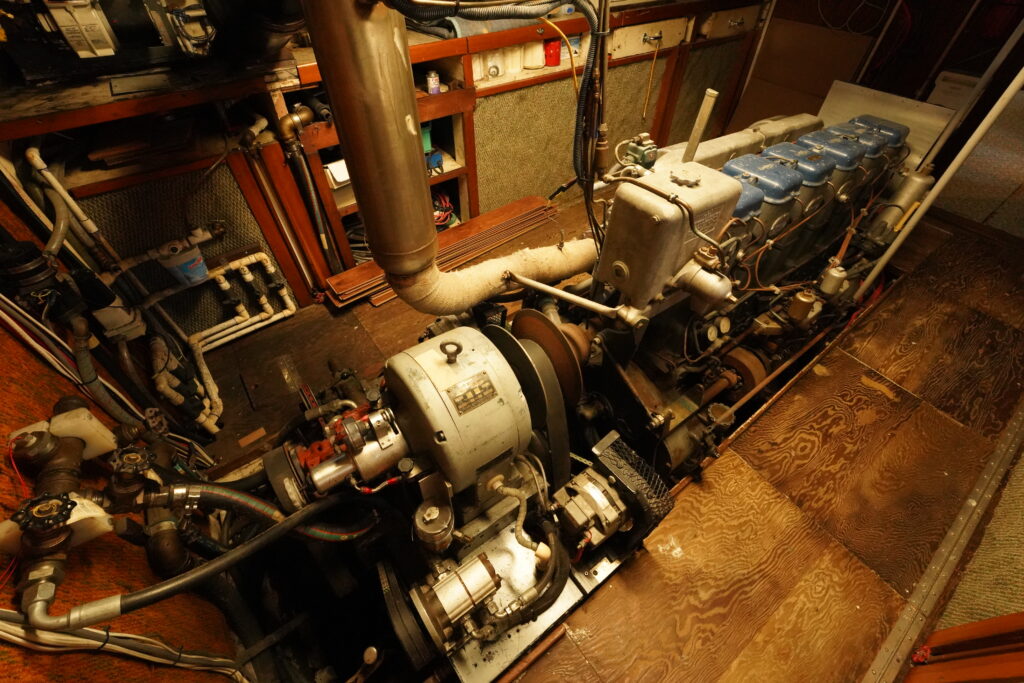

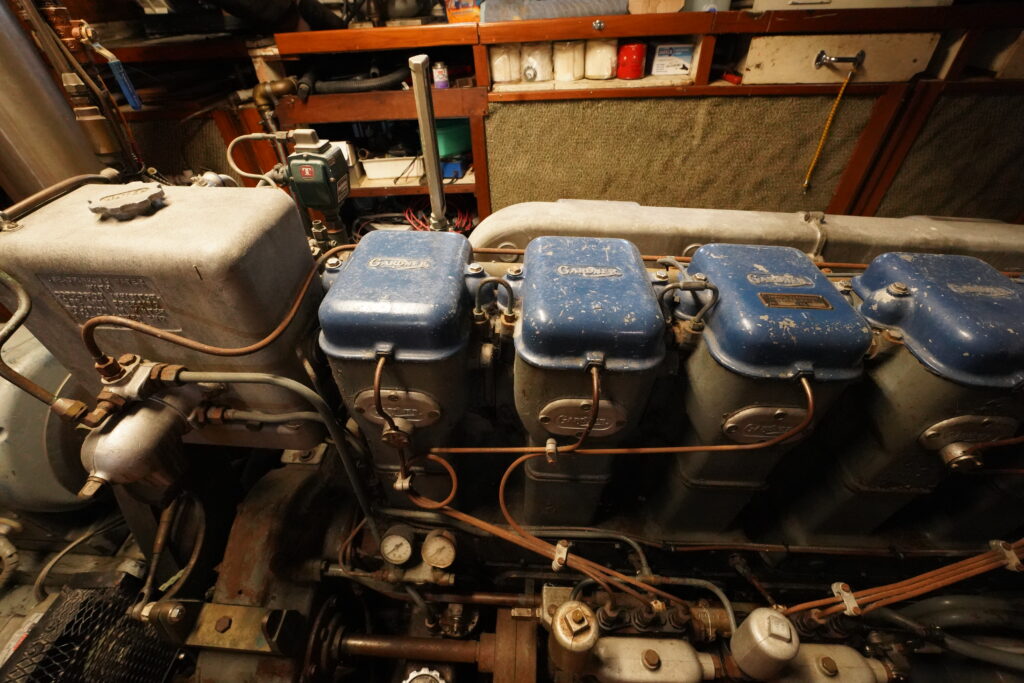

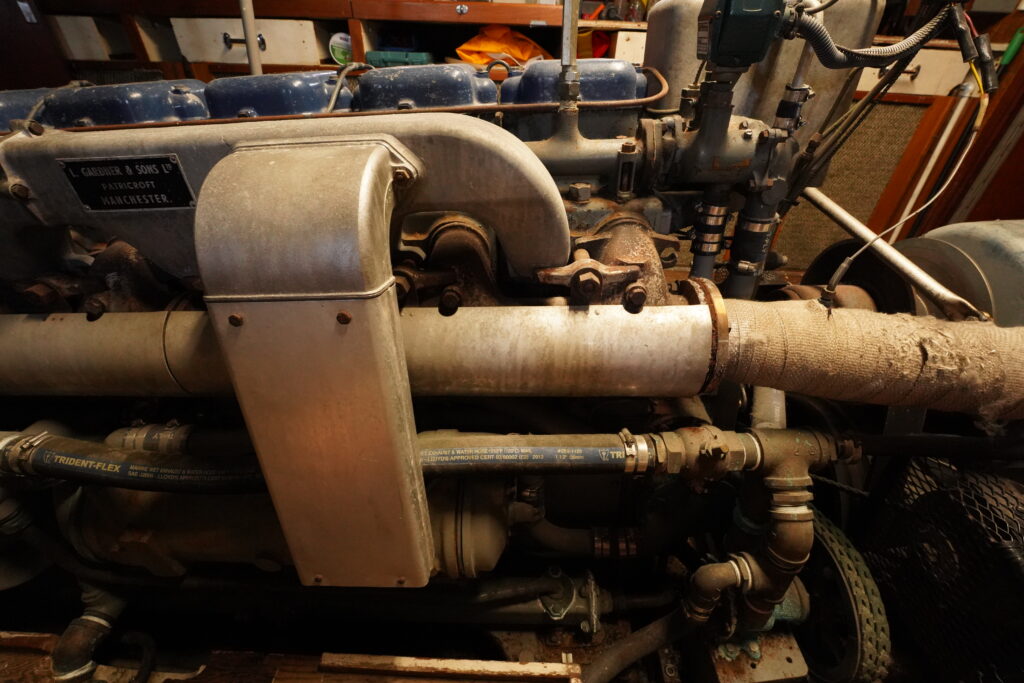

She has two large double doors on the aft deck that lead to a wide salon with generous windows. Moving forward is a U-shaped galley with full sized refrigerator. Forward is the interior helm and controls. As you go down below there are two cabins, one being a v-berth forward, a cabin with two bunks on the starboard side, with a head and shower port of the bunk cabin. As you keep going aft the engine room is square in the center of the boat housing the Gardner 6 cylinder LXB diesel engine with all mechanical and electronics. Moving aft is the master stateroom with its own dry head.

There are steps going up to the flybridge where there is a Lund dinghy with 30hp outboard that can be lifted with a hydraulic winch on a boom.

This hull is reported to be constructed with stainless rod and copper nickel mesh. This cannot be confirmed by observation, hardware mesh is observable in the inside of the hull. The decks and bulkheads appear constructed of 3/16″ rod and hardware mesh with Ferro cement binder.

She has been used as a liveaboard for the last seven years and below are some of the updates items that should be addressed:

- New 110V dryer in 2022

- New 4K inverter in 2019

- Dishwasher and ice maker have been disconnected due to not needing them and water usage – they work, just need to be added back to the panel.

- Furnace needs to be replaced (the hydronic system is in great condition, just needs a diesel boiler). We heated with two infrared heaters and were plenty warm all year.

- Hydraulic system works well. (davit, stabilizers, etc…)

- Both heads have had the macerator pumps replaced in 2023 (not a fun job, so at least they don’t have to do it for a while!).

- Shore power was converted to dual 30 amps that can run off of a single pigtailed 50 amp or a single 30 amp. (you can only run one side of the power if you do that).

- Shore power upgraded to Smartplugs in 2020

- 220 stove top disconnected due to using too much power (we use a dual convection cooktop).

- Decking refinished with Kiwi Grip in 2021

- Bottom needs to be cleaned and painted; it was last painted in 2018.

- New zincs in Jan. 2023. (large zincs on the back of the boat) These were changed from a custom made version to a much more economical and readily available version at that time.

- 24v and 12v system

- New 110 panel (teak/marine) and wiring for shore power in 2022.

- New wood floors in 2018 everywhere except the master stateroom and engine room.

- Stand-up engine room with walkways on both sides.

- Hydraulic davits and windlass.

More about Ferro-Cement Boats:

There are considered to be six periods in the chronology of Ferro cement boatbuilding; 1) up to 1900 2) WWI 3) between the war years 4) WWII 5) 1955 – 1977 & 6) 1976 to 1996.

Early photo documentation is evident of a boat built in 1848 by Joseph Louis Lambot in Merival France, who patented the name “fericememt” in 1855. Another built in Belgium dates back to 1887. Carlos Gabellini of Rome has provided photographic evidence of Ferro boats from the 1890’s. It is believed that similar techniques date as far back to the Roman Empire.

Facts & Fallacies about Ferro-Cement boats; (excerpts from Hartley Boatbuilders, U.K.)

1) A 30′ 8 ton displacement sailboat built in Ferro-cement weighs 8 tons. A 30′ 8 ton displacement sailboat built in GRP/FRP weighs 8 tons. A 30′ 8 ton displacement sailboat built in wood weighs 8 tons.

2) GRP/FRP (glass or fiber reinforced plastic), is a method of construction developed from SRP (steel reinforced plaster), now known as Ferro-cement

2a) The advantage of the action of Osmosis on ferroboat hulls, is reversed to a disadvantage on GRP/FRP constructed hulls.

3) A wood constructed boat with a hole in it will sink at the same rate as a Ferro-cement one.

4) Nothing lasts forever, not even a ferroboat.

5) the biggest disadvantage of a Ferro-cement hull in the eyes of the surveyor, is it’s almost unique individuality.

6) An estimated 11,000 Hartley ferroboats have been built worldwide..

7) The first solo crossing of the Tasman Sea, was made in a home built ferro-cement Hartley Tasman 33′.

8) The earliest known ferroboat still in existence, was built by Lambot in France in 1848.

9) The country to have built the most vessels in ferro-cement is the U.K.

10) Boats have been built in ferro-cement from 10ft to 20,000 tons.The smallest and largest “Hartley ferroboats”, that have been designed are a 12′ dingy and the 130′ Steam Yacht “Backwater Lady”.

11) The British designed a 120′ submarine in Ferro cement.

The Canadian builder Samson marine is the best known here in the northwest where they built several vessels in both British Columbia and in their facility in Tacoma Washington. I had the pleasure, as a young shipwright, of having a tour of their facility in Tacoma in the mid-seventies where they were building a 54′ William Garden design offshore cruising ketch. The welded stainless steel framework was durable enough to have probably been wrapped in canvas for a seaworthy vessel. Once completed, the hull finish could not be more fair in any other method of construction. I recall seeing a test plank that was about 12 feet long, a foot wide and an inch thick that that would bend and twist as much, or more than any wooden plank without cracking or splintering demonstrating the ability of the ferro-cement boat to “work” at sea. Samson built numerous offshore sailing yachts as well as their trawler hulls the “C-Fisher’ 54 & ” C-Gleaner’ 44 designs by P. Noble .

Name: Iris Inez

Boat Type: Trawler

Condition: Fair

Accomodations

3 cabins, 2 heads with lots of space to cruise the world or liveaboard.

There is a large master stateroom aft of the boat, with the two remaining cabins forward of the engine room.

The main level features the inside helm station, galley, and large salon.

There is a covered flybridge with helm station and large Lund dinghy.

Electronics

Depthsounder

Log-Speedometer

Compass

GPS

VHF

Generator

Navigation Center

Wind Speed and Direction

Autopilot

Plotter

Radio

Shore Power Inlet

Inverter

Mechanical

| Engine Make | Gardner |

| Engine Model | 6 Cylinder LXB |

| Engine Hours | ~2600 |

| Engine Year | 1973 |

| Total Power | 177hp |

| Engine Type | Inboard |

| Drive Type | Direct Drive |

| Fuel Type | Diesel |

| Propeller Type | 3 Blade |

| Propeller Material | Bronze |

Inside Equipment

Dishwasher (needs to be connected)

Refrigerator

Washing Machine & Dryer

Electric Bilge Pump

Oven

Microwave Oven

Marine Head

Heating

Hot Water

Refrigerator

Deep Freezer

Fresh Water Maker

Battery Charger

Outside Equipment

Davit(s)

Dinghy/Tender

Fin Stabilizer